Flame Spray Molybdenum Wire

Flame spray

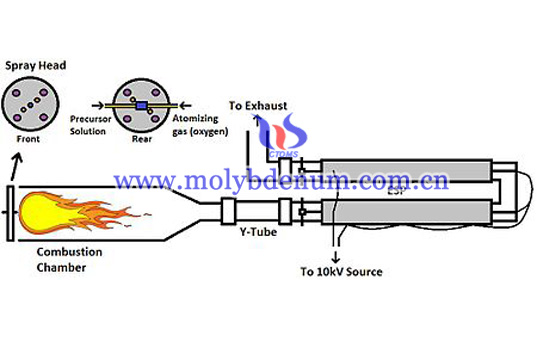

Flame spray is a method to produce spray molybdenum wire. In the flame spray process, powder or wire materials are melted through the release of chemical energy triggered by a combustion process. A fuel gas (or liquid) is burned in the presence of oxygen or compressed air. Acetylene fuel gas is most frequently selected, due to its high combustion temperature of 3100°C and low cost. Propane, hydrogen, MAPP, and natural gas are also common choices. The flame melts the feedstock, and also accelerates and propels the molten particles. Compressed shop-air is also used to assist and boost the particle velocities. However, a compressed inert gas such as argon or nitrogen is preferred if oxidation is a concern.

The setup of a flame spray of producing spray molybdenum wire system is relatively inexpensive and mobile. A basic setup requires only a flame spray torch, a supply of oxygen, and a fuel gas. To increase safety, the setup might have to be augmented with an enclosed spray booth and exhaust.

Because its particle velocities are lower than those of the other thermal spray processes, flame spray coatings are usually of lower quality; they have higher porosity and lower cohesive and adhesive strengths. However, coating quality can be improved by a "spray-and-fuse" process. After the coating is applied by flame spray, the combustion process is repeated to raise the substrate temperature to the point at which the previously applied coating starts to melt. Fusing temperatures exceed 1040°C. The final coating is extremely dense and well-bonded by a metallurgical bond. A disadvantage of this technique is the high substrate temperature required and the possibility for deformation of the part.

If you have any interest in spray molybdenum wire, please feel free to contact us by email: sales@chinatungsten.com sales@xiamentungsten.com or by telephone: 86 592 512 9696.