Plasma Spray Molybdenum Wire

Plasma spray

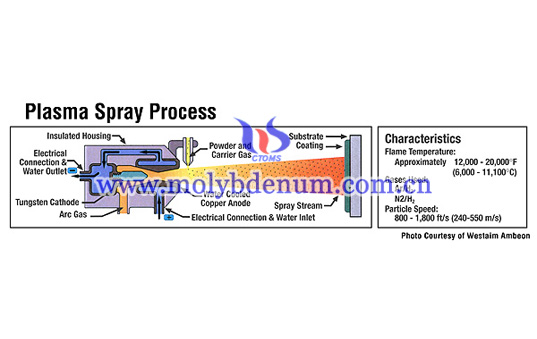

Plasma spray is a method to produce spray molybdenum wire. The plasma spray process requires a plasma gun or torch to generate an arc, which creates the plasma by ionizing a continuous flow of argon gas that is injected into the arc.

The arc is struck between a water-cooled copper anode and a tungsten cathode. This type of process is also referred to as non transferred arc spraying, because the arc is confined to the plasma gun. It is generally operated at energies in the neighborhood of 40 to 100 kW.

The plasma is a conductive gas with an extremely high internal working temperature (around 10,000°C). However, little heat is transferred by the plasma, so the part being sprayed remains relatively cool. For example, the making spray molybdenum wire process temperature of an 8-kg part will stay around 100°C. Because of the high internal operating temperature, this process is ideally suited for spraying high-melting-point materials such as ceramics and refractory metals.

The high heat of plasma causes a large increase in the volume of inert gas introduced, and this produces a high-speed gas jet that accelerates the molten particles and propels them toward the substrate at high velocities. High particle velocities result in dense coatings with high bond strengths.

The plasma transferred arc (PTA) process is somewhat of a hybrid between plasma spraying and welding. In this process, an arc is struck between the non consumable electrode of the plasma torch and the workpiece itself. The feedstock, in the form of wire or powder, is introduced into the resulting external plasma. The material is melted and puddled onto the substrate, producing a metallurgical bond similar to welding, but with a lot less dilution. This process of using plasma spray to produce spray molybdenum wire is capable of producing dense and smooth coatings, but it is not capable of applying ceramics.

If you have any interest in spray molybdenum wire, please feel free to contact us by email: sales@chinatungsten.com sales@xiamentungsten.com or by telephone: 86 592 512 9696.