Thermal Spray Molybdenum Wire

Thermal spray

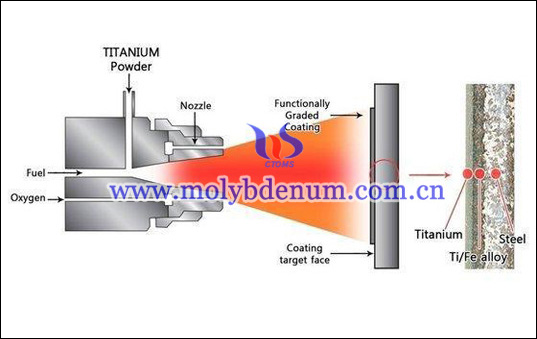

Thermal spray is a method to produce spray molybdenum wire. Thermal spraying is generic term used to define a group of processes that deposit finely divided metallic or nonmetallic materials onto a prepared substrate to form a coating. The coating material may be in powder, rod or wire form.

The thermal spray gun to produce spray molybdenum wire uses plasma arc, combustible gases or an electric arc to generate the heat necessary to melt the coating material. The material changes to a plastic or molten state when heated and is accelerated by process gases. The acceleration of the molten material produces a confined stream of particles that the process gases transfer to the substrate. The particles strike the substrate, flatten upon impact, and form thin platelets that bond to the substrate and to each other. The particles build up and cool into a lamellar structure that forms a coating.

The thermal spray process is synergistic. System components, parameters and the desired coating functions and properties must be determined to select the type of material and equipment needed for the process. The process may be tailored for particular application after establishing this information.

Various coatings can be achieved by using different combinations of equipment and consumables. Basic thermal spray producing spray molybdenum wire systems typically consist of a spray gun, powder supply or gas control console and a wire or powder feeder.

Thermal spray processing is a well established way of forming coatings of thicknesses greater than about 50 micrometers, so-called thick coatings. A wide range of materials can be thermal sprayed for a variety of applications, ranging from gas turbine technology (heat engines) to the electronics industry.

Thermal sprayed coatings have been produced for at least 40 years, but the last decade has seen a virtual revolution in the capability of the technology to produce truly high performance coatings of a great range of materials on many different substrates. This enhancement of the technology has been achieved largely through the introduction of new spray techniques, the enhancement of spray process controls, by employing state-of-the-art methods of feedstock materials production, and through the use of modern techniques of quality assurance.

If you have any interest in spray molybdenum wire, please do not hesitate to contact us by email: sales@chinatungsten.com sales@xiamentungsten.com or by telephone: 86 592 512 9696.